| Machine Dimensions |

| Footprint (with controller) |

21’8” x 17’3” to 48’9” x 19’2”

(6,604 mm x 5,258 mm to 14,859 mm x 5,842 mm) |

| Weight (tank empty) |

12,000 lbs to 30,000 lbs

(5,443 kg to 13,607 kg) |

| Height (with scissor plumbing) |

14’0” (4,267 mm) |

| Operating Weight |

48,630 lbs to 117,160 lbs

(22,060 kg to 53,142 kg) |

| Work Envelope |

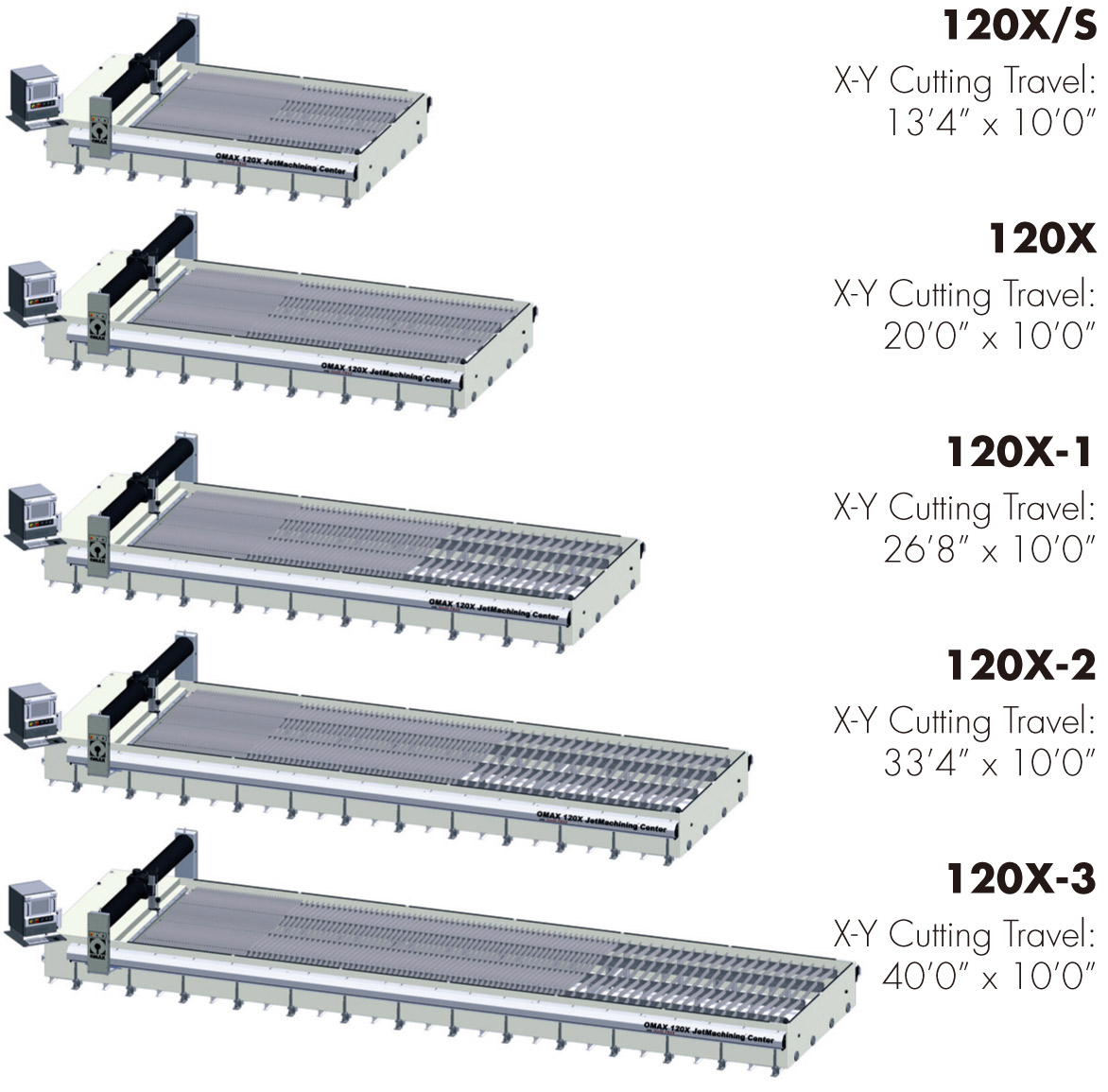

| X-Y Cutting Travel |

13’4” x 10’0” to 40’0” x 10’0”

(4,064 mm x 3,048 mm to 12,192 mm x 3,048 mm) |

| Z-Axis Travel |

8” (203mm) |

| Table Size |

14’11” x 11’5” to 41’10” x 11’5”

(4,547 mm x 3,480 mm to 12,751 mm x 3,480 mm) |

| Drive Description |

- Closed loop, digital drives

- Brushless servo motors

- IntelliTRAX drive technology with linear encoders in X-Axis

- Precise Motorized Z-Axis

|

|

| Standard Model Specifications |

| Material Support Slats |

4" x 1/8" Galvanized Steel |

| Maximum Supported Material Load |

400 lbs/ sq ft (1,950 kg/ sq meter) |

| Electrical Requirements |

3-Phase, 380-480 VAC ±10%, 50-60 Hz |

| Noise Level |

Below 80dBA at one meter for submerged cutting |

| Speed |

350 in/ min (8,890mm/ min) |

| Linear Positional Accuracy |

±0.001" (±0.025mm) |

| Repeatability |

±0.001" (±0.025mm) |

| Ballbar Circularity |

±0.005" (±0.127mm) |

| Optional Accessories |

- Tilt-A-Jet Cutting Head

- Variable Speed SRS (VS-SRS)

- Collision Sensing Terrain Follower (with Tilt-A-Jet only)

- Z-Axis Drill

- Precision Optical Locator (POL)

- Water-only MAXJET 5 for cutting soft materials

- OMAX Mini MAXJET 5i Nozzle Assembly

- DualBRIDGE second bridge

- Manual Tilt Z

- Second MAXJET 5i with Motorized Z-Axis (requires second Y-Axis carriage)

- Large Solids Removal System

- Laminar Filter

- Waterjet Brick Kit

- Rotary Axis

- Air and Water Conditioning Kit

- A-Jet

- Terrain Follower/A-Jet

- Material Holding Kit

- Laser Feature Finder

(see more...)

|

| *Optional accessories may reduce cutting travel. Photos may show optional accessories. For a complete list of accessories, contact an OMAX sales representative. Accuracy specifications are at 72° F (22° C) Pumps are built to meet UL and CE specifications. Contact OMAX for detailed utility requirements. |